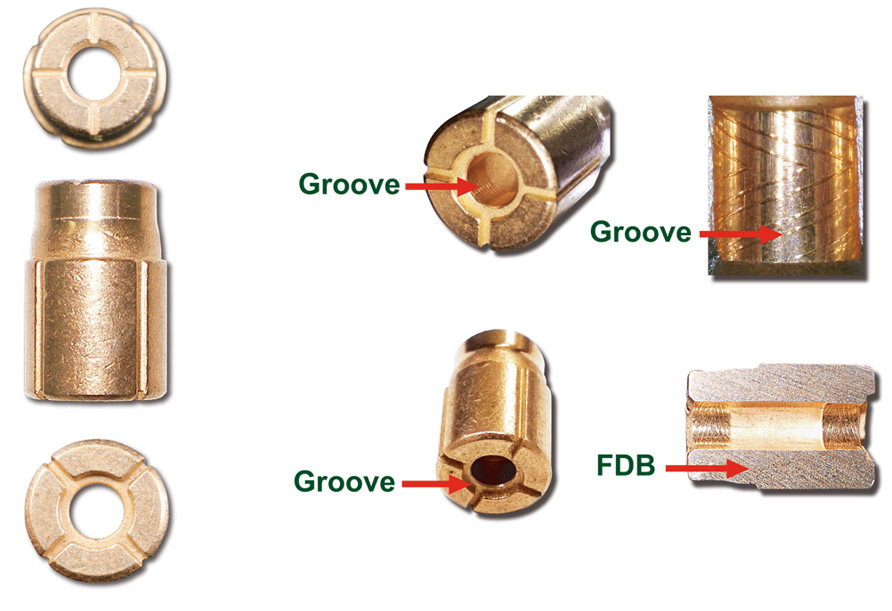

Our company’s name is “Jialian Technology Ltd.”, the main product is Herringbone Groove Fluid Dynamic Bearing (HGFDB) which is suitable for high quality rotating parts such as fans, motors, flywheels, and gyroscopes, etc. The innovative technology is to process the inner diameter surface of the bearing and make the grooves with special programs and special tooling. This kind of sintered copper alloy bearing with herringbone groove and recirculation groove on the outer diameter surface will generate dynamic oil pressure when it is running at high speed. The herringbone will gather lubricating oil concentrating and average distributing naturally between shaft and bearing to keep a stable rotation. It is called HGFDB, which is currently the most effective among various fluid dynamic bearing in the world.

HGFDB has low friction and long life. Please refer to the pictures to realize the mysteries more easily. We obtain fifteen patents in five countries. The excellent performance is the most suitable for motors and rotating parts that pursue high speed and high quality. Herringbone Groove Fluid Dynamic Bearing (HGFDB) is a product with micron-level and high precision. It plays an indispensable and important role in the global electronic, fan-motor and electric appliance markets where products tend to be light, thin, short and small, and pursue for high efficiency, high speed and high quality. Jialian-Tech insists on technology innovation, implements quality assurance system, concentrates on environmental protection and energy saving, and executes standardized production management to provide the highest quality bearings which can help customers upgrade their fans, motors, flywheels and gyroscopes, etc. to the leading high end product. HGFDB has entered the global market which makes Jialian Technology the best partner for rotating parts of the electronic, fan-motor and electric appliance industries.

| Type | ID mm | OD mm | Lg mm |

|---|---|---|---|

F12 F12 |

1.2 | 4.0 | 3.5 to 5.0(4.0 / 4.6) |

F15 F15 |

1.5 | 4.0 | 3.5 to 5.0 (4.0/4.6) |

F20 F20 |

2.0 | 5.0 | 4.5 to 8.0 (5.0/5.6/8.0) |

F30 F30 |

3.0 | 8.0 | 6.5 to 13.0 (9.0/11.0/12.0) |

Various types of fans, motors, flywheels, and gyroscopes, etc. have different types and sizes of bearings that respond to the different kinds of operations. As long as it is a directional rotating part, all can use the precision sealed Herringbone Groove Fluid Dynamic Bearing (HGFDB) of Jialian Technology to improve the quality of your products and extend the service life. Our HGFDB has a simple appearance, it doesn’t need to apply preload spring and it is easy to install and assemble. In particular, ultra-high-speed fan motors are used in household appliances, drones, servers, and precision instruments. It is more effective to use our HGFDB to lower vibration and reduce noise. If currently listed, specifications do not meet your products, the newer size can be designed according to the customer’s request when there is a large demand. If you would like forward information about your product, please contact with us.

The reason was shown in the pictures to explain how Herringbone Groove Fluid Dynamic Bearing (HGFDB) generates dynamic pressure. The gray is the shaft, the yellow is the bearing and the red is the lubricating oil. When the shaft rotates in the forward direction, the herringbone groove gathers the lubricating oil to the tip and generates fluid dynamic pressure. It forms an oil film between shaft and bearing to prevent friction. At the same time, the dynamic pressure concentrating the shaft to reduce the radial deflection caused by external force and starting. This important function can’t be achieved by other brands of bearing. Only HGFDB wins the first prize. However, it is very difficult to process a uniform herringbone groove in the curved surface of a narrow inner hole. Jialian-Tech. has completely overcome the difficulties, developed unique manufacturing technology, established an entire lots production system, and gradually expanded production capacity to meet customer’s needs.

The traditional DC brushless fan motor is commonly used for heat dissipation in Servers, Computers, Game Hosts, Power Supplies, and Communication Rooms. The bearing system of the traditional DC Brushless Fan Motor has “two Ball Bearings” (2B or BB), and there are also “one Ball and one Sleeve Bearings” (1B1S or BS) in order to save costs. There are also cheaper “two Sleeve Bearings” (2S or SS) or “one Sleeve Bearing” (1S or S). These styles can all be replaced with a” Herringbone Groove Fluid Dynamic Bearing” (abbreviated as HGFDB or HG) to improve the quality of the fan and upgrade it to a long-life fan. It can also break through the bottleneck of high speed, and provide a solution for the heat dissipation requirements of huge data flow and huge heat sources in the era of 5G and 6G communication. Anyhow, you can achieve the desired results with one try.

Herringbone Groove Fluid Dynamic Bearing (HGFDB) can be used in Fan and Motor market. It can also be used in many different marketing fields, such as Optics motors, Servo motors, Spindle motors, Trail motors, Axial flow fans, and Centrifugal flow fans and Blowers. HGFDBs are especially important supporters of high-speed flywheels, gear transmission systems, motors, gyroscopes, and other precision rotating parts. HGFDB can promote the above rotating systems to a quiet, long-life grade. They are the best partners of all rotating parts, and they are the most outstanding new favorite of the bearing industry in this high-speed generation.

Herringbone Groove Fluid Dynamic Bearing (HGFDB) has characteristics of long-life, low vibration, low noise, high damping, and is suitable for high rotation. It can be widely used in motors, fans, flywheels, gyroscopes, and other markets. HGFDB of Jialian-Tech is quite different from traditional Sleeve/Cu-alloy/Cu-tube bearings, though there is all similar shape. HGFDB uses a special formula include refined copper alloy, by processes of forming with pressure, sintered in high temperature, cleaning in supersonic, impregnating with lubricant in a vacuum. It can accept more ring stress, be more porous, and have more oil storage. The unique Herringbone Groove and lubricant will generate a magical dynamic oil pressure when the shaft is rotating to form a uniform cylindrical oil film. The bearing generates uniform radial damping around the shaft. It will concentrate the shaft to avoid metal friction and contact effectively. This is an important function that other brand bearings can’t match.

Jialian Technology has developed the exclusive lubricating oil GF500 for Herringbone Groove Fluid Dynamic Bearing (HGFDB), which is the most suitable lubricant for immersing in the pores of sintered copper alloy and can effectively establish a dynamic oil pressure damping film. GF500 is a fully synthetic oil with a wide range of working temperatures. Its volatility and creeping loss rate are extremely low, and it contains anti-gelling and anti-precipitated formulas which can form the best dynamic pressure in the herringbone groove and will not grow filthy grease for a long time. It can totally protect the bearing and the shaft to maintain the normal operation. Its performance is unparalleled. It is the highest quality bearing lubricating oil. The bearings used in traditional fans, motors, flywheels, and gearboxes, etc., sleeve bearings (S, SS, BS) are mostly used for low level and low-speed ones, and ball bearings (BB) are used for high level and high-speed ones.

In the era of 5G and 6G communications, PC/NB, game computers, and servers with high data flow and high heat sources all require high-speed cooling fans. High-speed hair dryers, instant hand dryers, high-resolution aerial cameras, intelligent drones, and precision gyroscopes all require ultra-high-speed and low-noise motors. Ball bearings will encounter some bottlenecks including expensive, high-frequency noise, short-life, friction and heating from the shaft and the inner ring, etc. Once the above bearings of goods switch to HGFDB, almost all troubles will be solved. The high-level ones enjoy the following advantages: quietness, long-lived, durability, and cost down. The lower ones can easily upgrade, increase competitiveness and open up new markets. Choosing HGFDB is a wise choice!

Our Herringbone Groove Fluid Dynamic Bearing (HGFDB) has related patents in five countries, including Taiwan (R.O.C.), China, the United States, Japan, and Germany, and has fifteen patent items. The patent content of the design of structure, herringbone groove, leakage prevention, and so on. In addition, new design projects are being developed one after another.